Latest commission was for a West End, London musical! Propworks required a foot bellows (new to me) that would produce a good blow of air…

A quick visit to my timber mill friends at Vastern Timber in Wootton Bassett to find a lovely piece of pippy oak with a requested ‘not new look’, a visit to a local upholsterer to select an aged spring and a selection of subdued Lincoln Green leather. A lot of thinking, a lot of nervous construction – I never know if everything will work together successfully until the bellows is completed. Now appearing in Theatre Royal Drury Lane – let’s wish them a long run!

Big and Small

Finished a rebuild of a small fireside bellows and could not resist photographing them with the partially finished Field Forge bellows (see below) …

Although repairs to bellows are usually far from economic, these small bellows were an achievable challenge -“air only blows out the hole, not the nozzle…” Found problem: glue pushed into a hole in the wood where nozzle attached – enough to fill the nozzle!

New leather, a cleanup of the wood, fresh tacks and a cleared nozzle made a huge difference, especially as they produced a good flow of air.

Thank you so much – they look amazing! D&C – Owners

Medieval Field Forge Bellows

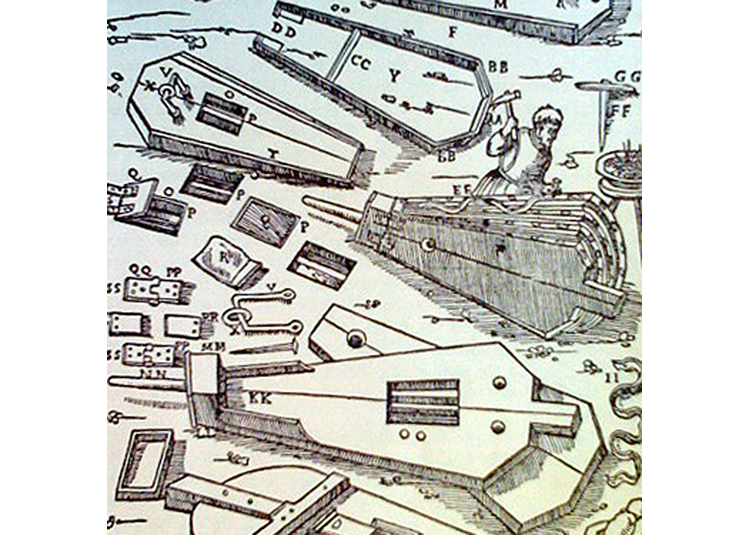

A friend who is a blacksmith and participated in medieval reenactments, asked for some field forge bellows – that set me off on an interesting journey of research. As it turned out, a shortish journey as there was no specific information available. I did find an image of a woodcut print in a book of machines of the 1500’s – but no specs.

These bellows need to behave differently to the fireside bellows. A steady stream of air is required to keep the forge at an ideal heat, so forge bellows have double ‘lungs’. They are also much bigger! Full forge bellows can be around 6 feet in length, with a number of panels, so are not portable like those used in the field. I decided around 1 metre long without the nozzle by roughly 60cm would produce more than enough air while being possible to transport. Dimensions of the round valve holes as well as the nozzle outlet required quite some thought!

Needed around half a cow (not literally!) to provide a single piece of leather to enclose the lungs of the bellows, so some wrestling with that, and a lot of tacks hammered in while I had no idea that all my calculations would result in effective bellows until finished.

2023. Bellows finished! AND, they work perfectly!! Phew!

Blacksmith friend added the forged nozzle and built a strong frame that can be dismantled for transporting to reenactments*. It has been quite a journey…

*Reenactments are no longer attended by my friend so, “Yes, they are for sale or hire.” Contact me if interested.